How Much Does Custom Metal Cutting Cost?

If you’re looking to get custom metal parts cut with waterjet or fiber laser technology, you might be wondering how much it costs. The truth is, pricing depends on several factors, including material, thickness, cutting method, and design complexity. In this guide, we’ll break down the key cost factors so you can plan your project and get the best value.

1. Material Costs

The type of metal you choose plays a big role in pricing. Common materials and their approximate cost per pound include:

-

Steel: $0.50 – $1.50 per lb (varies by grade)

-

Aluminum: $2.00 – $3.50 per lb

-

Stainless Steel: $2.50 – $5.00 per lb

-

Brass & Copper: $3.00 – $7.00 per lb

Exotic metals like titanium or Inconel cost more due to sourcing and cutting difficulty. Some materials are more readily available, while others may have higher costs due to supply chain fluctuations.

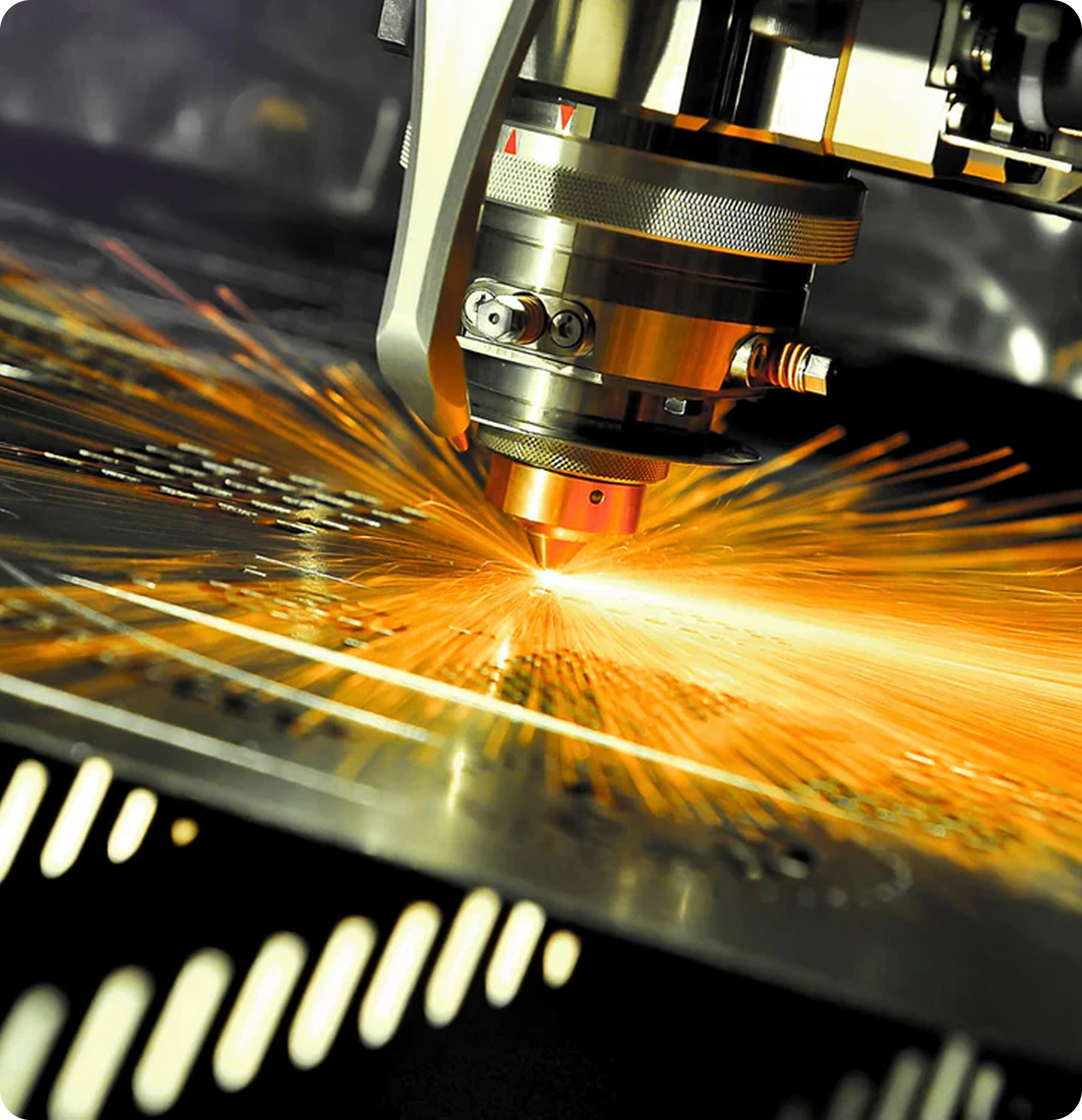

2. Cutting Method: Waterjet vs. Fiber Laser

Both cutting methods have different costs associated with them:

-

Waterjet Cutting: Great for thick materials and no heat-affected zones.

-

Fiber Laser Cutting: Faster and more cost-effective for thin to medium-thickness metals.

More intricate designs or thicker materials may require additional processing time, which can slightly increase costs.

3. Design Complexity & Cutting Time

The more complex the design, the longer it takes to cut, which affects pricing. Factors that increase costs include:

-

Fine details and small cutouts – Slows down the cutting process

-

Thicker materials – Requires more energy and time to cut

-

Longer cutting paths – More inches of cutting = higher cost

At 1CutFab, we optimize your design to minimize cutting time and material waste, helping to keep costs as low as possible.

4. Quantity Discounts

Larger orders often come with lower per-unit costs. Many custom cutting shops, including 1CutFab, offer price breaks for bulk orders. The more parts you order, the more you save on setup and processing fees.

5. Additional Fees to Consider

-

Material Markup: If we provide the material, there’s a standard markup to cover sourcing and handling as well as waste.

-

Setup Fees: Small orders may have a minimum charge due to programming and setup costs.

-

Bending or Post-Processing: If your part requires bending, expect a charge per bend (typically $1-$5 per bend, depending on complexity).

-

Shipping Costs: Larger or heavier parts will have higher shipping fees.

Getting an Accurate Quote

For the most accurate pricing, upload your design to our quoting system at 1CutFab.com. Our system calculates costs based on real-time material pricing, cut time, and order quantity.

Final Thoughts

Custom metal cutting isn’t one-size-fits-all, but understanding these cost factors can help you budget effectively. At 1CutFab, we’re committed to providing high-quality cutting services at competitive prices. Got a project in mind? Get a quote today!