Why Choose 1CUT FAB for Waterjet Cutting?

1CUTFAB can deliver high-quality, affordably-priced waterjet parts with fast turnarounds. Here's what you can expect from our waterjet cutting service:

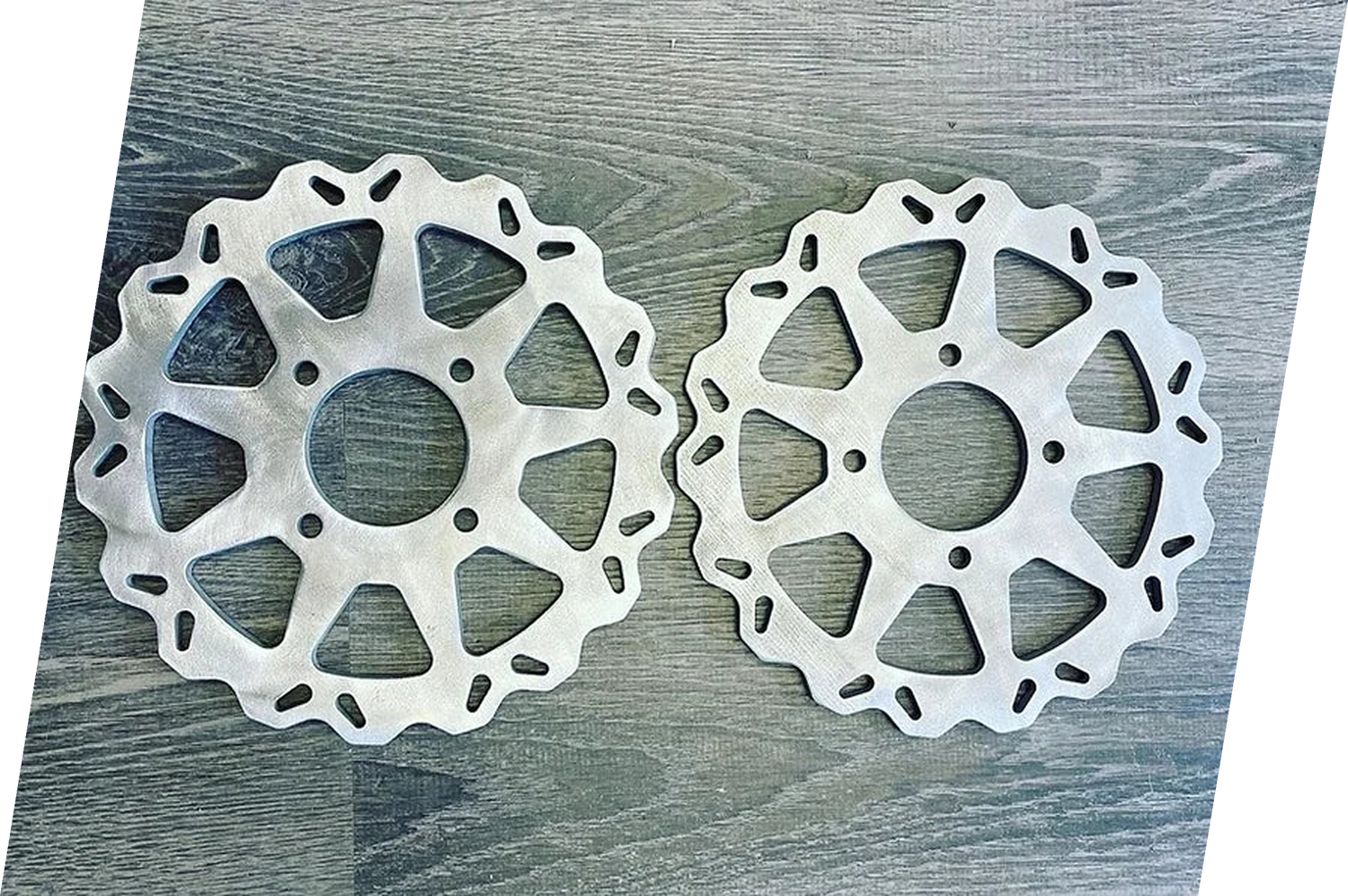

High Quality Cuts

Our Omax GlobalMax waterjet cuts materials precisely at a high tolerance, free from distortion. This technology achieves precision parts and complex shapes that would otherwise be difficult to produce, making it a vital tool for your needs.

Superior Edge Quality

Waterjet allows for superior edge quality through the use of sand, high-pressure water, and precise nozzle sizing. This method produces Clean, accurate cuts with minimal distortion, far surpassing other cutting approaches.

Wide Range of Materials

Our waterjet cutting process can effectively cut a diverse range of materials in varying sizes and thicknesses that may not be attainable through laser or plasma cutting methods. Moreover, our waterjet technology makes it possible to cut through materials like rubber, plastic, composites, glass, stone, and ceramic with great accuracy.

Waterjet Advantages Over Laser or Plasma cutting

Water Jet cutting boasts several advantages over other methods, such as plasma or laser cutting. It generates smooth edges, eliminating the need for additional work. Unlike its alternatives, waterjet cutting doesn't lead to burn marks, cracks, or work-hardening of materials. Plus, with waterjet cutting, thick materials can be cut no problem with greater precision.

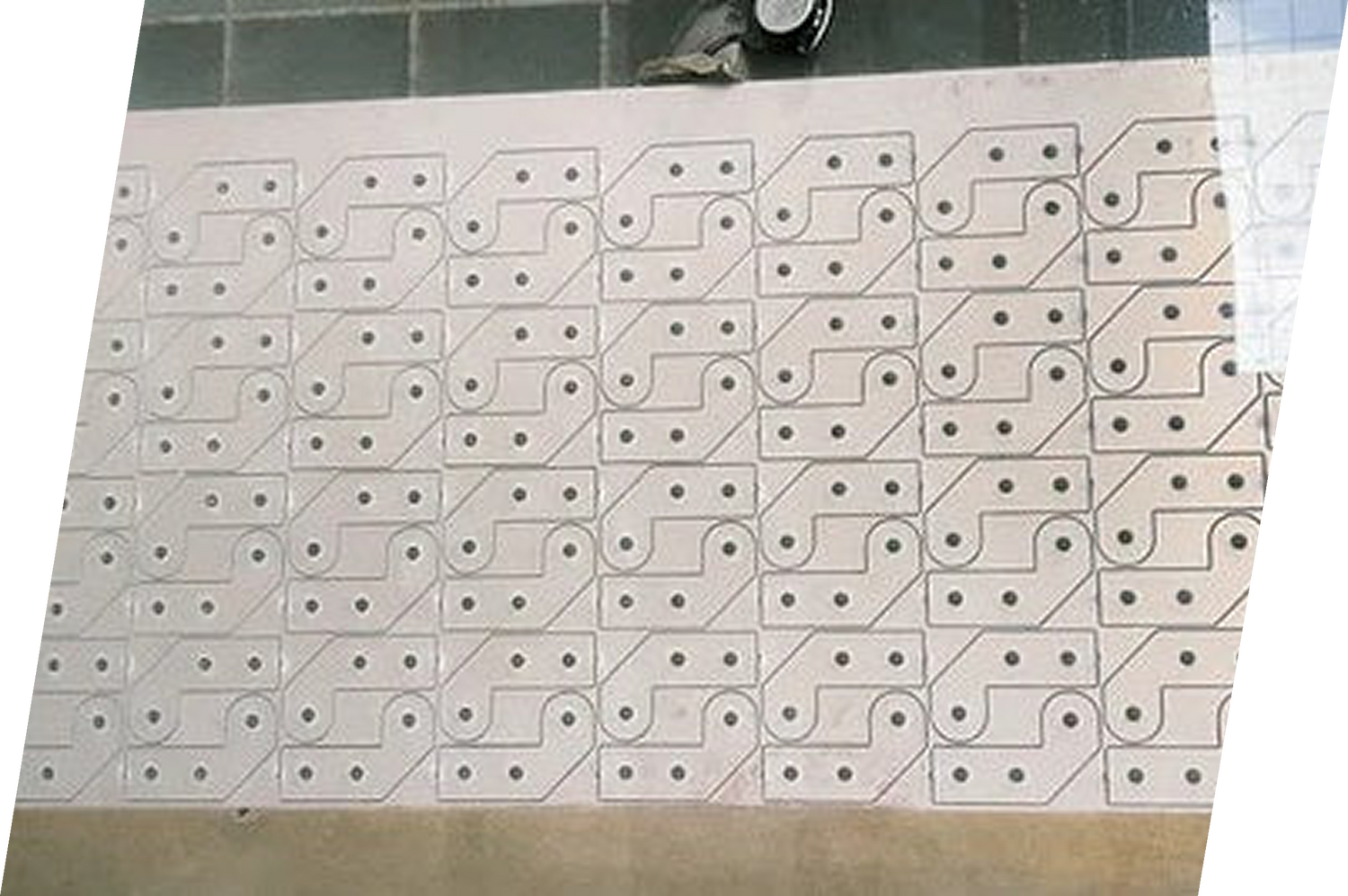

Minimal Waste

1CUTFAB utilizes cutting-edge software to efficiently nest parts, minimizing waste and saving customers money.

Omax Globalmax 2040 Waterjet

Our WaterJet, a 6'8" x 13'3" GlobalMax 2040 at 1CUTFAB, cuts almost all materials. Capable of accommodating full-size sheets, it's perfect for saving time, material, and ultimately money! From 72" wide by over 144" long parts to up to 6" thickness, we've got you covered!

Get Your instant Waterjet Quote Today!

Upload your file, pick a material, get your instant price! Our team will do our best to accommodate you to ensure you are happy with the end product. For more information or if you have any questions send us a message and we will do our best to take care of you.