A Beginner’s Guide to Sheet Metal Bending!

If you've ever wondered how flat sheets of metal become parts of cars, appliances, or even airplanes, you're in the right place. This Beginner’s Guide to Sheet Metal Bending breaks down the basics in plain English. Metal bending is the process of reshaping sheet metal without removing any material. It’s used in everything from small DIY projects to massive industrial manufacturing. Whether you're a hobbyist or just curious about how things are made, understanding metal bending opens the door to countless creative and practical applications. Let’s dive into the essentials you need to know.

Common Bending Methods

When it comes to sheet metal bending, not all methods are created equal. Each technique serves a unique purpose depending on the material, thickness, and the type of bend required. In this Beginner’s Guide to Sheet Metal Bending, understanding these common bending methods is essential for getting the results you want.

-

V-Bending:

This is the most widely used method. A V-shaped die and punch are used to form the metal into the desired angle. It’s ideal for general-purpose bends and works well with most sheet metals. -

Air Bending:

Air bending involves pressing the sheet into a die without bottoming it out. This method allows for flexibility with bend angles and uses less force, reducing tool wear. -

Bottoming:

Also known as bottom bending, this method pushes the sheet all the way into the die. It provides higher precision but requires more force. -

Coining:

A high-pressure technique where the punch and die fully press into the metal, causing permanent deformation. It’s extremely accurate and used for precision parts. -

Roll Bending:

Perfect for creating curves or cylindrical shapes, roll bending uses three rollers to gradually form the sheet into a curved profile.

Knowing these methods helps you choose the right one for your project, saving time and preventing costly mistakes.

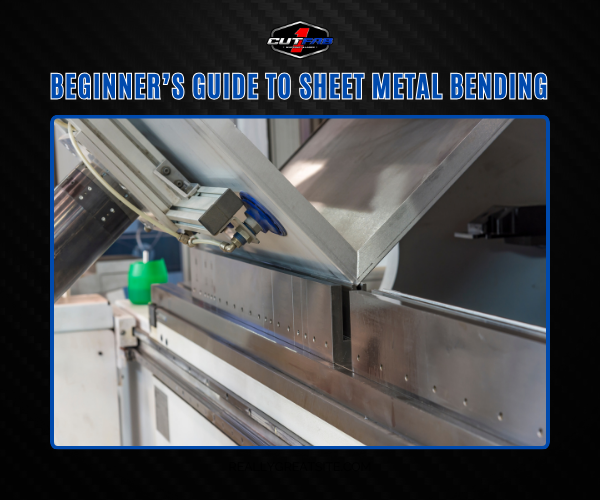

Tools & Machines Used in Sheet Metal Bending

In this Beginner’s Guide to Sheet Metal Bending, one key factor to success is understanding the tools and machines behind every precise bend. Whether you're working in a garage or managing a full-scale fabrication shop, using the right equipment makes all the difference in accuracy, efficiency, and safety.

1. Manual Tools:

For small-scale projects and DIY work, hand tools like bending brakes, clamps, mallets, and seamers are incredibly useful. These allow you to make simple bends by hand, especially for thinner gauges of metal.

2. Press Brakes:

This is the workhorse of most professional metal shops. A press brake uses a punch and die to bend the metal sheet. It can be manual, hydraulic, or CNC-controlled. CNC press brakes, in particular, offer high precision and are perfect for complex, repeatable bends.

3. Folding Machines:

These machines clamp the sheet and fold the edge upward or downward. They’re great for bending large panels or creating boxes and enclosures.

4. Roll Benders:

Ideal for making large curves or cylindrical shapes, roll benders gradually shape the metal by feeding it through a set of adjustable rollers.

5. Specialized Dies and Punches:

From V-dies to offset punches, selecting the right die for your machine is crucial for achieving clean, accurate bends.

Understanding your tooling options helps you avoid trial-and-error mistakes and maximizes productivity. Whether you’re a beginner or scaling up, having the right tools transforms your sheet metal bending experience.

Material Considerations – Springback, Thickness

One of the most overlooked—yet critical—elements in sheet metal bending is understanding the material itself. In this Beginner’s Guide to Sheet Metal Bending, we can't stress enough how factors like springback and material thickness impact your final product.

Springback:

Springback refers to the metal’s tendency to partially return to its original shape after bending. It happens because metals have elastic properties that resist permanent deformation. The higher the yield strength of the material, the more springback you’ll encounter. For instance, stainless steel has more springback than aluminum. To compensate, fabricators often "over-bend" slightly beyond the desired angle so the final shape settles where it needs to be.

Material Thickness:

Thicker metal requires more force to bend and usually results in larger bend radii. It also influences the choice of tooling—using the wrong die for a thick sheet can result in cracks or warped parts. On the other hand, thin materials bend easily but are more prone to distortion if not handled correctly. Always match the punch and die width to the material gauge for best results.

Pro Tip: Use bending calculators or software when planning your bends. These tools factor in thickness, bend radius, and springback, helping you get it right the first time.

Understanding how material properties affect bending can save you time, money, and a lot of frustration. It’s not just about force—it’s about finesse.

Applications – Enclosures, Custom Parts

Now that you’ve got a handle on the basics, let’s look at how sheet metal bending is applied in the real world. In this Beginner’s Guide to Sheet Metal Bending, understanding where and how these techniques are used can give you a whole new appreciation for what’s possible.

1. Electrical Enclosures:

One of the most common uses of sheet metal bending is in the creation of electrical enclosures. These protective casings are used to house sensitive components in everything from consumer electronics to industrial machinery. Bending allows for clean, secure edges and flanges that improve both structural integrity and safety. Plus, using CNC machines ensures tight tolerances that meet industry standards.

2. Custom Parts for Machinery:

From brackets and panels to supports and housings, custom metal parts are everywhere. Sheet metal bending allows manufacturers to produce unique components that fit perfectly into a larger assembly. Whether you’re retrofitting an old machine or prototyping a new product, bending gives you the flexibility to create one-offs or scale up production.

3. Automotive and Aerospace Uses:

Need lightweight but strong parts? Sheet metal bending delivers. It’s ideal for making structural parts, dashboard frames, and more—without sacrificing precision.

4. DIY and Maker Projects:

Even hobbyists use bending to create shelves, cases, toolboxes, and custom mods. It's affordable, customizable, and incredibly rewarding.

No matter the industry, sheet metal bending offers a combination of strength, precision, and adaptability that few fabrication methods can match.

Tips & Best Practices

Mastering sheet metal bending takes more than just the right tools—it’s about technique, planning, and avoiding rookie mistakes. In this Beginner’s Guide to Sheet Metal Bending, here are some proven tips and best practices that will save you time, money, and frustration.

1. Always Measure Twice, Bend Once

Precision matters. Even a few millimeters off can ruin a part. Use digital calipers, layout tools, or bending software to confirm dimensions before you touch the metal.

2. Account for Springback

Don’t forget—your material will try to return to its original shape. Always over-bend slightly to compensate. Test on scrap metal first to dial it in.

3. Use the Right Tool for the Job

Match the punch and die to your material’s thickness and bend radius. Using mismatched tooling leads to inaccurate results and even cracks.

4. Mind Your Bend Orientation

Always bend perpendicular to the grain direction of the metal (if applicable). This reduces the risk of cracking and ensures a smoother bend.

5. Don’t Skip Safety

Sharp edges, heavy machinery, and high pressure mean safety gloves, goggles, and proper training aren’t optional—they’re essential.

Following these best practices helps ensure cleaner results, longer tool life, and a much smoother fabrication process overall.

Conclusion

Sheet metal bending might seem complex at first, but with the right knowledge, tools, and techniques, it becomes an accessible skill for beginners and pros alike. This Beginner’s Guide to Sheet Metal Bending has walked you through the essential methods, tools, materials, and real-world applications. Whether you're crafting enclosures, custom parts, or diving into DIY projects, understanding the basics is your first step toward bending like a pro. Keep learning, keep experimenting—and remember, precision is power.