Everything you need to know about Metal Bending

Metal bending is a process that can be used to create a variety of shapes and objects from sheet metal. The process usually involves using a machine to apply pressure to the metal in order to bend it into the desired shape. There are many different types of machines that can be used for this purpose, each with its own advantages and disadvantages. In this blog post, we'll take a look at some of the most popular methods of metal bending so that you can decide which one is right for your needs.

1. Hand Bending

One of the most basic methods of metal bending is hand bending. This method is typically used for projects that require only a small amount of bends or for projects where precision is not critical. To bend the metal by hand, you'll need to use a pair of pliers to grip the metal at the point where you want to make the bend. Then, simply apply pressure until the metal bends to the desired angle. One advantage of hand bending is that it requires no special equipment, so it can be done anywhere. Additionally, hand bending is very versatile and can be used to create a variety of shapes and objects. However, one downside of this method is that it can be difficult to achieve precise bends. Additionally, because you'll be relying on your own strength to bend the metal, this method is only suitable for small-scale projects.

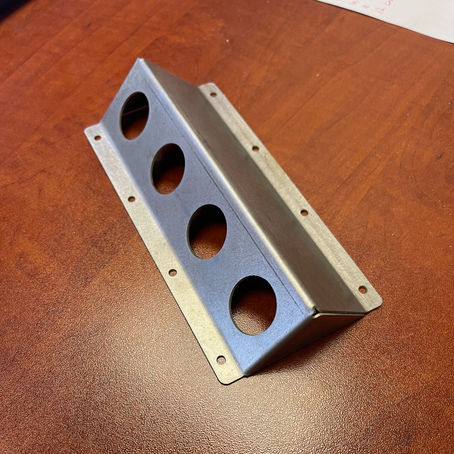

2. Press Brakes

Press brakes are machines that use hydraulics or electromechanics to apply pressure to the metal, thereby creating a bend. Press brakes come in a wide range of sizes and styles, so there's sure to be one that's perfect for your needs. One advantage of press brakes is that they allow you to create precise bends with ease. Additionally, press brakes can handle much larger pieces of metal than can be bent by hand, so they're ideal for large-scale projects. However, one downside of press brakes is that they can be expensive to purchase or rent. Additionally, because they require special training to operate safely, they're not suitable for everyone.

3. Rolling Mills

Rolling mills are another type of machine that can be used for metal bending. Rolling mills work by feeding the metal through a series of rollers that gradually reduce its thickness. This process also has the effect of lengthening and stretching the metal, which makes it possible to create long curves and bends. One advantage of rolling mills is that they allow you to create long, smooth bends with ease. Additionally, because rolling mills stretch the metal as well as reducing its thickness, they're ideal for creating complex shapes. However, one downside of rolling mills is that they require special training to operate safely, which means they might not be suitable for everyone.

Metal bending is a process that can be used to create a wide variety of shapes and objects from sheet metal. There are many different methods of metal bending, each with its own advantages and disadvantages. In this blog post, we've taken a look at some of the most popular methods so that you can decide which one is right for your needs.