The Best Material to Waterjet Cut According to Experts

When it comes to waterjet cutting, the choice of material can greatly impact the efficiency and quality of the process. Experts in the field have identified certain materials that are best suited for waterjet cutting, based on their properties and characteristics.

What are the top materials for waterjet cutting?

According to experts, some of the best materials for waterjet cutting include:

- Stainless Steel: Known for its durability and resistance to corrosion, stainless steel is a popular choice for waterjet cutting.

- Aluminum: Lightweight and malleable, aluminum is another material that is well-suited for waterjet cutting.

- Carbon Fiber: With its high strength-to-weight ratio, carbon fiber is often used in industries where lightweight yet strong materials are required.

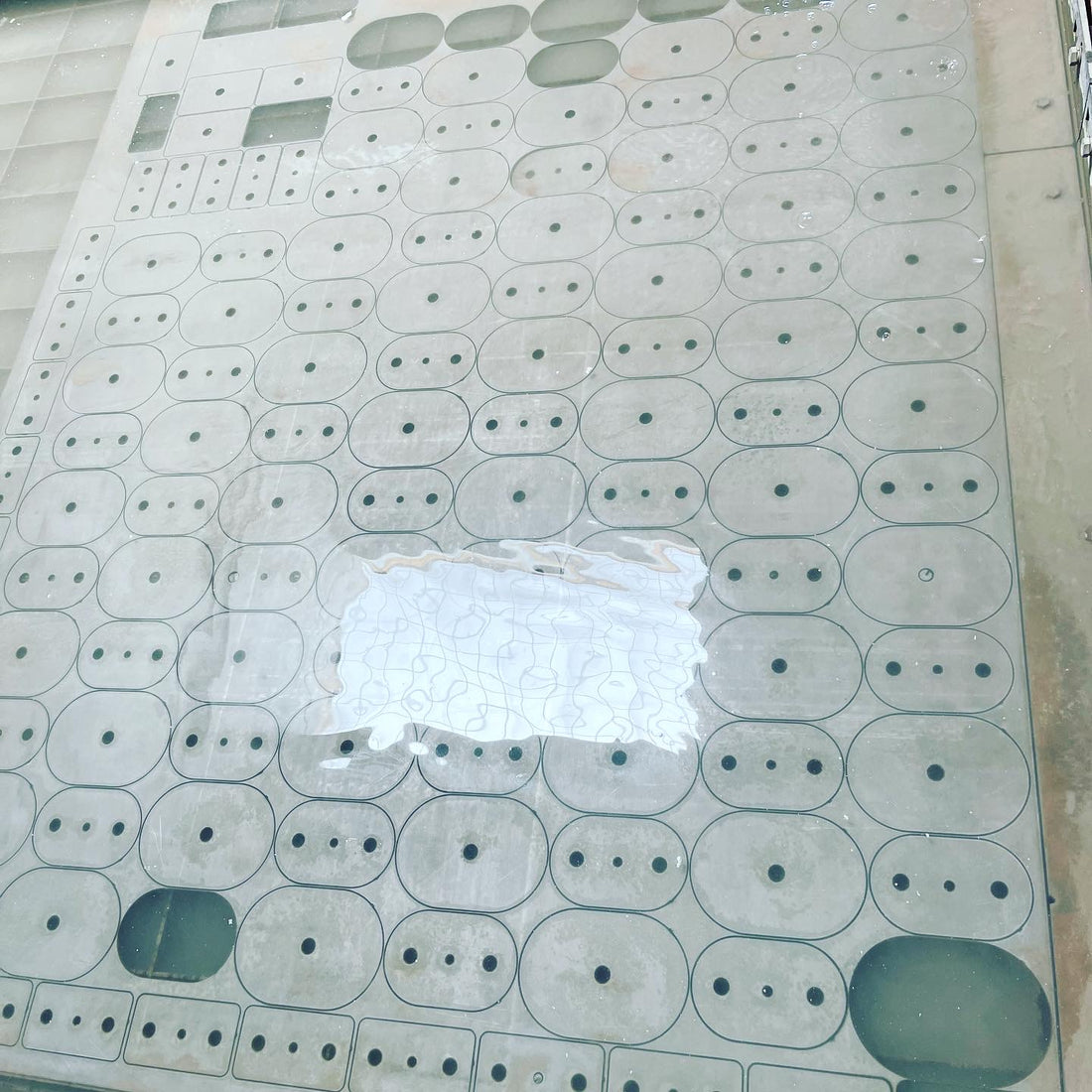

- Glass: Surprisingly, glass can also be effectively cut using a waterjet, making it a versatile material for various applications.

Why are these materials ideal for waterjet cutting?

These materials are considered ideal for waterjet cutting due to their unique properties. For example, stainless steel's hardness and resistance to heat make it a suitable candidate for precision cutting. Aluminum's softness and ductility allow for clean cuts without deformation. Carbon fiber's strength and lightweight nature make it a perfect choice for intricate designs. Glass, despite its fragile reputation, can be cut with precision using a waterjet, making it a versatile material for artistic and industrial purposes.

Overall, the best material for waterjet cutting ultimately depends on the specific requirements of the project. Consulting with experts in the field can help determine the most suitable material based on factors such as thickness, hardness, and desired outcome.