Top 10 Benefits of Laser Cutting

Laser cutting is a versatile and precise method of cutting various materials with the use of a high-powered laser beam. It has revolutionized the manufacturing industry and has become an essential tool for many businesses. In this blog post, we will explore the top 10 benefits of laser cutting.

1. Precision

Laser cutting offers unparalleled precision, allowing for intricate and complex designs to be cut with accuracy. The laser beam is controlled by computer software, ensuring precise cuts every time.

2. Versatility

One of the greatest advantages of laser cutting is its versatility. It can cut a wide range of materials, including metals, plastics, wood, fabric, and more. This makes it a valuable tool for various industries, from automotive to fashion.

3. Speed

Laser cutting is a fast process, making it ideal for high-volume production. The laser beam can cut through materials quickly, reducing production time and increasing efficiency.

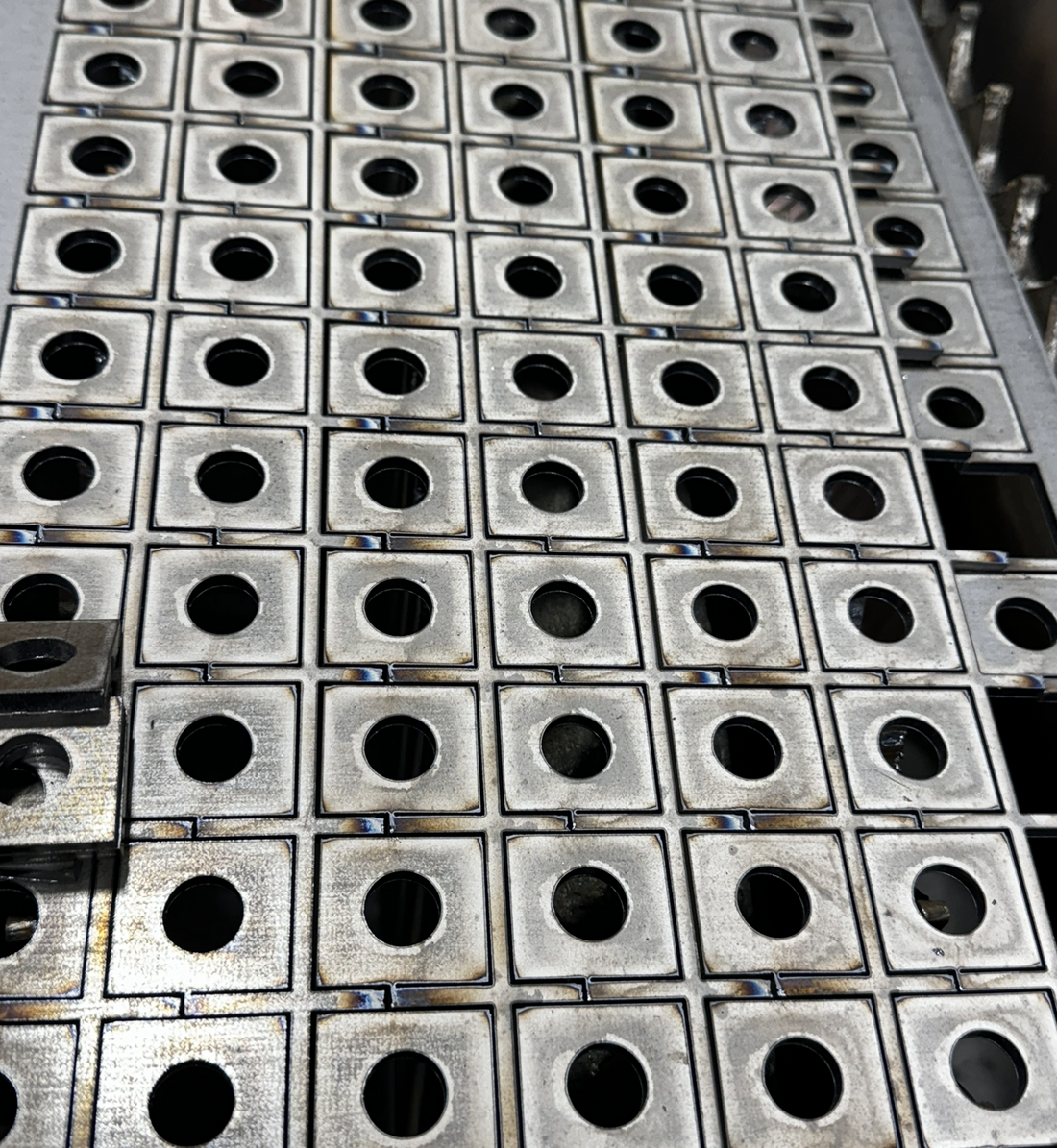

4. Clean Cuts

Unlike traditional cutting methods, laser cutting produces clean and precise cuts. There is no need for additional finishing or polishing, saving both time and money.

5. Minimal Material Waste

With laser cutting, the laser beam melts or vaporizes the material, resulting in minimal material waste. This is especially beneficial for expensive materials or projects with tight budgets.

6. No Contact

Laser cutting is a non-contact process, meaning there is no physical contact between the laser and the material being cut. This eliminates the risk of damage or distortion to the material, ensuring a high-quality end product.

7. Flexibility

Thanks to its precise and versatile nature, laser cutting allows for intricate and complex designs to be easily achieved. It can cut intricate patterns, small holes, and even engrave designs onto the material.

8. Automation

Laser cutting can be easily automated, reducing the need for manual labor and increasing productivity. This is particularly advantageous for large-scale production or repetitive tasks.

9. Cost-Effective

While laser cutting machines may have a higher upfront cost, they offer long-term cost savings. The precision and efficiency of laser cutting reduce material waste, labor costs, and the need for additional finishing processes.

10. Safety

Laser cutting is a safe process when proper safety measures are followed. The laser beam is enclosed within the machine, minimizing the risk of accidents or injuries. Additionally, the non-contact nature of laser cutting reduces the risk of material damage or distortion.

In conclusion, laser cutting offers numerous benefits, including precision, versatility, speed, clean cuts, minimal material waste, and more. It has revolutionized the manufacturing industry and continues to be an essential tool for businesses worldwide.